电子mg官方网站

你们的物料是连续加工还是分批加工? Different applications require different types of flows through the production line.

连续混合过程 are characterized by a consistent flow of material through the mixer where the discharge rate exactly matches the feed rate. The primary benefit of continuous mixing is steady state throughput to feed the next processing operation on the production line.

另一方面、批量混合工艺 通常都不处于稳定状态. Premeasured ingredients are added to the mixer, processed, 和 discharged in a single batch. The major benefit of batch mixing are the precise control of ingredient ratios 和 mix quality, as well as the ability to perform multiple operations (such as granulating) with the same machine.

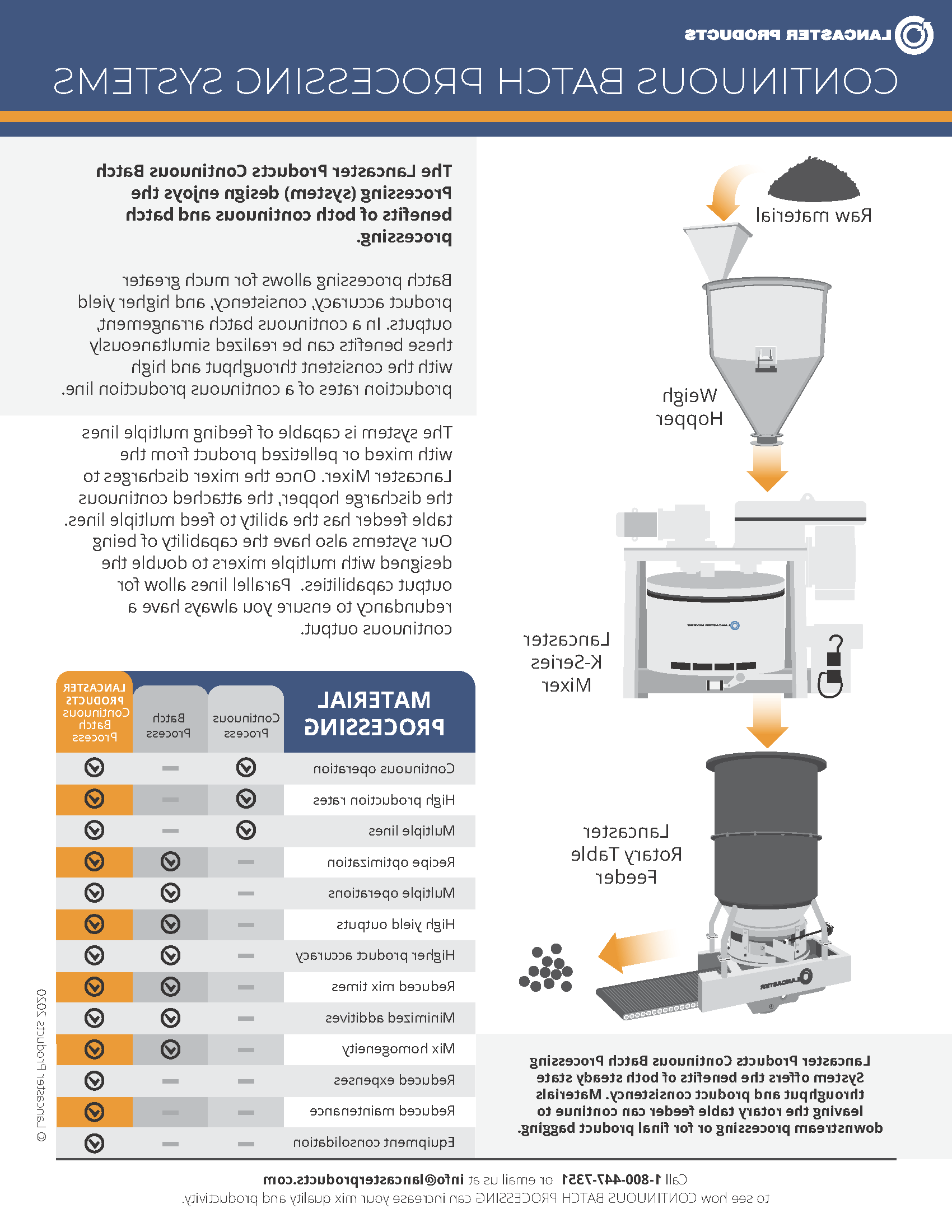

The 电子mg官方的电子mg官方 电子mg官方网站 (system) design enjoys the benefits of both continuous 和 batch processing. 批处理允许很多 greater product accuracy, consistency, 和 higher yield outputs. In a continuous batch arrangement, these benefits can be realized simultaneously with the 一致的吞吐量 和 高产量 一个连续的生产线.

电子mg官方网站:一种混合选择

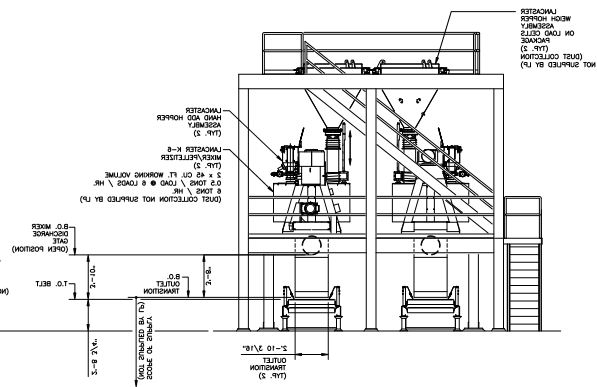

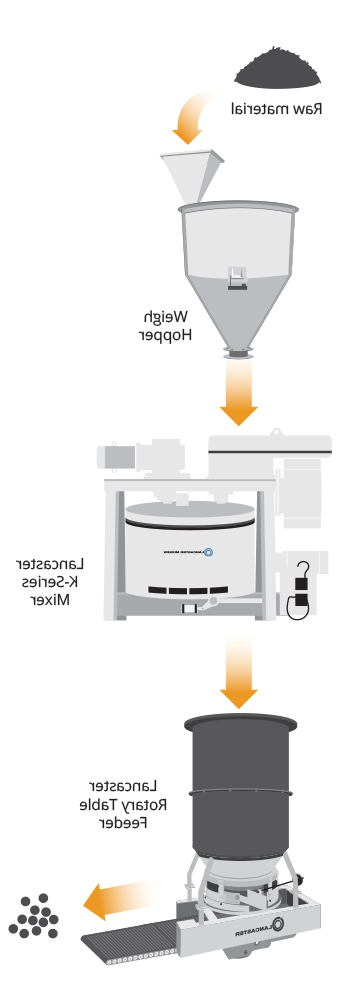

电子mg官方电子mg官方利用上面和下面的漏斗 高剪切混合器 交付电子mg官方网站过程. Weigh hopper(s) above the mixer utilize load cells to pre-weigh the ingredients. 一旦搅拌器准备好了,就可以做新一批了, 滑阀被打开, 重力可以让搅拌器快速填充. 当料斗空了, this slide valve will close to allow the weigh hoppers to prepare the next batch of ingredients to be mixed. The hopper directly below the mixer is called a discharge hopper. This hopper allows the mixer to discharge the entire batch, so that the mixer can be refilled. 然后,卸料斗将物料送入管道 连续台式给料机 或者传送带. 搅拌器下面的这些料斗的尺寸通常至少为1.5 times the size of the mixer, ensuring a continuous material flow to the downstream processes.

电子mg官方电子mg官方电子mg官方网站系统设计

In a typical 电子mg官方的电子mg官方 High Shear Counter Current Mixer system, 将称重后的干料进行干混合. Then, if required, wet additives or binders are metered in, 和 a 湿混合 is completed. 最后, 如果期望的最终电子mg官方有尺寸要求, the system moves to a granulating or pelletizing cycle before discharge. 所有这些步骤都在一台机器上完成, 无需中间物料搬运步骤, complex process control of multiple machines or added inefficiency.

The 电子mg官方的电子mg官方 system is capable of feeding multiple lines with finished products. 一旦混合器卸料到卸料斗, the attached 连续台式给料机 has the ability to feed multiple lines. Our systems also have the capability of being designed with multiple mixers to double the output capabilities. Parallel lines allow for redundancy to ensure you always have a continuous output.

在连续过程中混合成粒或成球

Granulating or pelletizing can easily be achieved within a continuous batch processing system by utilizing a Lancaster Mixer. 电子mg官方混频器功能 逆流混合技术 这样可以减少混合时间, 最小化添加剂, improved mix homogeneity as well as mixing 和 granulating/pelletizing in one-step. 反向旋转的锅和 多刀配置 results in superior mixing 和 granulation in the same machine 和 process.

The capability to independently control the speed of the pan, high speed rotor 和 plow results in the most desirable final mixed/pelletized product. Altering individual tooling speed allows the mixer to create exact 和 repeatable conditions 和 shear within the mixing cavity that produce specific products – such as pellets of a specific size within a tight tolerance. Even slight adjustments to the tooling speeds combination can produce different sized granules, 密度和产量. This gives the Lancaster Mixer the versatility to change the end product from batch to batch without altering the ingredients.

Traditional pelletizing processes require the raw material to be dried to less than 20%, 然后输送到粉碎机/磨粉机, 继续使用针式混合器, 和 then to a disc pelletizer or pellet mill before being conveyed to dryer. The 电子mg官方的电子mg官方 High Shear Counter Current Mixer can mill, 干拌混合料, 湿混合, 并在一台机器中制粒, with higher moisture levels than traditional granulation equipment. This significantly reducing capital expenditure, maintenance costs 和 square footage required. Learn more about the benefits of pelletizing in a Lancaster Mixer.

The 电子mg官方的电子mg官方 电子mg官方网站 system allows users the best of both worlds. 连续处理应用, users now can take advantage of the precision of a Lancaster Mixer to improve product quality 和 precision, increase production line yields 和 throughputs while reducing additives to precise amounts. 批处理应用, users can now take advantage of a continuous production flow to improve output without losing any of the precision of the batch process. The 电子mg官方的电子mg官方 电子mg官方网站 offering is a superior alternative to traditional production lines by offering the benefits of both types of processing with none of the drawbacks.

呼叫 1-800-447-7351 or 电子mg官方 to see how CONTINUOUS BATCH PROCESSING can increase your mix quality 和 productivity.